Innovation at Real Steel Knives

Explore the cutting-edge innovations behind our designs. At Real Steel Knives, we are constantly pushing the boundaries of knife craftsmanship to bring you the latest in performance, structure, ergonomics, and materials. Discover how our engineers and designers work together to redefine the future of EDC, bushcraft and tactical knives.

ATS: Spring Tension According

to Your Definition

ATS stands for "Adjustable Tension System," a system specially developed for slip joint folding knives that allows users to customize spring tension. The principle involves rotating an eccentric spacer sleeve (located at the handle’s center) to adjust the back spring’s position, thereby altering tension levels. Three settings are available: high,medium, and low. To adjust, simply turn the central screw clockwise with a wrench. The tension cycles through the sequence 0-1-2-3-2-1-0, with each level corresponding to a specific position.

Slide Safety Lock: Automatic

and Reliable

Designed by Carson Huang (2013), this feature combines intuitive operation with precision engineering. This supplemental safety mechanism for frame locks activates automatically upon opening the knife. To close the blade, slide the safety tab downward while disengaging the frame lock. A must- have for frame lock lovers with higher demands.

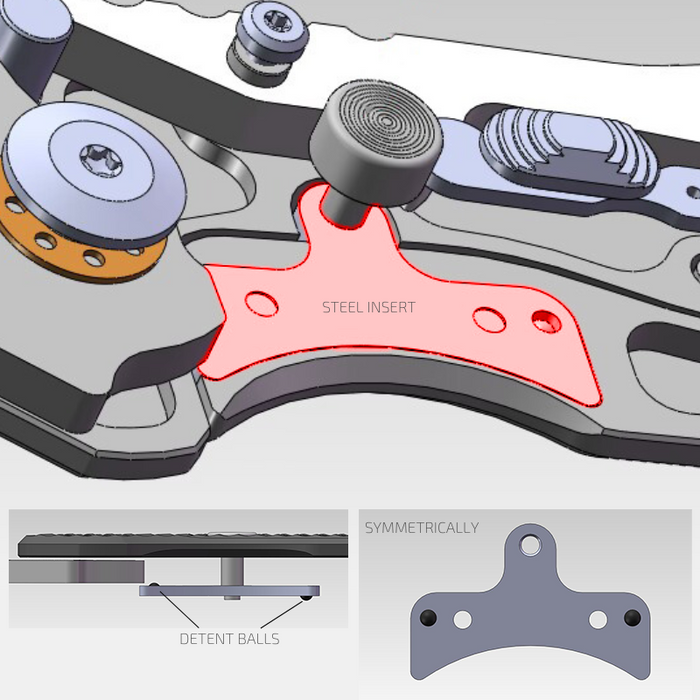

G10 Back Spring: Harmonious Color and Lightweight

While G10 composite is commonly used for handle scales, its application as a functional spring component is innovative. Key advantages include: Aesthetic Integration: Colors seamlessly match the handles. Reduced Weight: Enhances portability without compromising durability. Technical ingenuity ensures reliability: A steel insert at the blade contact point mimics the longevity of traditional steel springs. Rigorous stress and endurance testing guarantees performance, featured in our LUX series.

Integral Spine: Structural

Integrity and Weight Reduction

Crafted from a single folded sheet of metal, this unified handle replaces conventional double-plate designs. Benefits include:Enhanced Stability: Monolithic construction minimizes number of parts.Lower Mass: Streamlines overall weight. Precision machining ensures symmetrical alignment of components. Applied to crossbarlock models like Sacra and Perix, this design delivers unparalleled smoothness and tactile satisfaction during use.

Interchangeable Scales: Want to show off a new side of your knife?

The ability to replace the handle scales without affecting the construction is the wish of many fans, which RSK has now responded to. RSK's interchangeable scales have two main features: 1. After the scale is removed, the knife can still be used. 2. You only need to tighten/loosen a single screw on one side to change the scale. The first knife with this creation was the RB-5. RSK offers G10 in various colors, as well as titanium and copper scales.